Desired Coupling

Entering a Desired Coupling value in this field will tell JAVATC to adjust the coupling coefficient. Leaving this field blank or 0 will prevent JAVATC from adjusting the coupling and simply output the coupling coefficient at the coils current proximity's. JAVATC will adjust up to the maximum possible for vertical adjustments (max coupling occurs when the primary is centered in relationship to the secondary). If you see the output is less than you "desired", then the coil wasn't capable of the value you entered. A proximity change between coils would have to be manually performed by the user to increase it further.

The program uses the desired coupling value to physically adjust the coil to the desired coupling value. This is performed by computing the mutual inductance, calculating k, then raising or lowering the primary coil as needed. For the program, it is better to adjust the primary. Adjusting the secondary becomes overly complicated with topload objects (which would have to be uninstalled/reinstalled during the process). By adjusting the primary, the task is accomplished with minimal computation time.

JAVATC will help position the primary coil relative to the secondary coil at your desired value. But, use this only as an educated starting position. You will need to adjust coupling for optimum performance.

Coupling is directly related to energy transfer time from source to destination coil. In a Tesla coil, it is very rare for coupling to ever exceed 0.25 due to secondary voltage stress limitations. Some systems breakdown at much lower values of k. The time of energy transfer is directly related to the coupling coefficient and is measured from the instant the source coil begins transferring energy and ends when the destination coil is storing all of the energy which was transferred from the source coil.

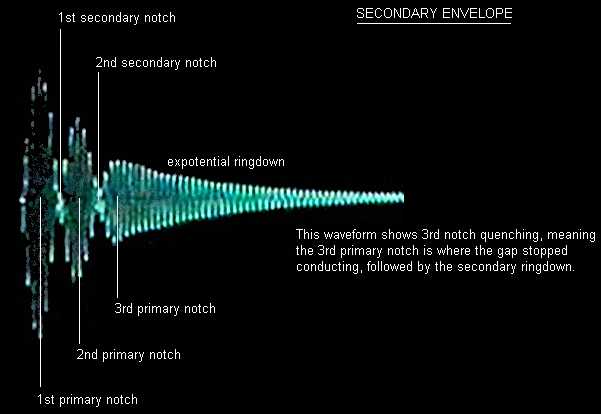

For typical coupling coefficients used on 2-coil resonant transformers (0.13 to 0.22), the total energy transfer (t0 > t1, t1 > t2, etc.) will take from 4 to 2.5 cycles at the coils resonant frequency. The faster the total energy is transferred (determined by the coupling coefficient) and the faster the gap stops conducting, the lower the losses seen in the system. But there are very real limitations to this. One is the voltage stress along the secondary form keeping k low. Another is gap quenching. To keep losses low (maximum energy to the spark channel), it makes sense to increase the coupling coefficient just under the voltage stress limit (electrical breakdown). This is performed by repositioning the proximity of the secondary and primary coils (usually vertically). Gap quenching is not so easy. For low bps systems, typical mechanical dwell times are too long to "force quench" the gap. Gap quenching is then dependent on how much energy is dissipated in the arc. Although increasing bps so the mechanical dwell time is near the energy transfer time may help force quench the gap, with faster bps comes less energy at the tank capacitor conducting across the gap more frequently. There are advocates on both sides of the issue on which is better or worse.